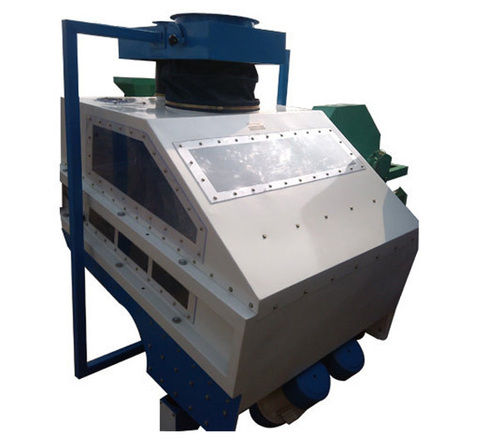

Destoner Machine

Destoner Machine Specification

- Automation Grade

- Automatic

- Operating Temperature

- Normal Room Temperature Celsius (oC)

- Speed Mode

- Single

- Frequency

- 50 Hz Hertz (HZ)

- Power Source

- Electric

- Machine Type

- Destoner

- Features

- Energy Efficient, Robust Construction

- Feeding System

- Vibratory

- Phase

- Three Phase

- Noise Level

- Low db

- Function Type

- Stone removal

- Product Type

- Destoner Machine

- General Use

- Removing stones from grains

- Type

- Grain Processing Equipment

- Capacity

- 2.5-3 T/h T/hr

- Weight (kg)

- 320 kg Kilograms (kg)

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 380V Volt (v)

- Power

- 2 HP Horsepower (HP)

- Dimension (L*W*H)

- 1850 x 950 x 1630 mm Millimeter (mm)

- Feature

- High Efficiency, Low Maintenance

- Color

- Blue & Silver

- Cleaning Efficiency

- Up to 99%

- Load Capacity

- Up to 3 Tons/hour

- Discharge System

- Automatic Outlet

- Applicable Grains

- Rice, Wheat, Pulses, Other Cereals

- Motor Speed

- 1440 RPM

- Air Flow Adjustment

- Manual

- Vibration Motor

- Heavy Duty, 2 HP

- Screen Area

- 0.8 m

- Adjustment Mechanism

- Inclined Sieve and Air Blower

- Body Finish

- Corrosion Resistant Paint

Destoner Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Destoner Machine

Destoner Machine manufactured by us is an automatic system which finds application for separation of stones from food grains. It is highly appreciated for having great specific capacity with easy maintenance & operation. This machine has been equipped with a fan, air recycling separator, airlock, air return duct, inlet & outlet, & aspiration connection. Destoner Machine is also equipped with rubber squeeze valves for creating discharge effect.

Features:

- Easy to change sieves

- Simple adjustment of air volume

- Provided with overload protection

Product Details:

|

Minimum Order Quantity |

1 Piece |

|

Capacity |

2 Ton |

|

Model |

MKIDS-2100 |

|

Automation Grade |

Semi-Automatic |

|

Motor Capacity (HP) |

3 |

|

Power |

7 kW |

Dependable Stone Removal for Grain Processing

This Destoner Machine is designed to provide superior cleaning for rice, wheat, pulses, and other cereals by efficiently separating stones and heavy impurities. With its inclined sieve and adjustable air blower, the unit delivers precise separation, ensuring that only clean grains move forward to the next processing step. The spacious 0.8m screen area and high-throughput vibratory feeding system make it an essential addition to mills, warehouses, and grain processing plants.

High Efficiency and Low Maintenance

Engineered for industrial durability, the machine incorporates a heavy-duty 2 HP vibration motor and automatic discharge system that together enable continuous operation with minimal downtime. Its corrosion-resistant stainless steel and mild steel body provide robustness for long-term use, while the energy-efficient design reduces operational costs. This reliable equipment requires little maintenance, underscoring its value for high-volume processing environments.

Advanced yet Simple Operation

Despite its advanced PLC control system and automatic operation, this destoner remains user-friendly, with manual air flow adjustment and a single-speed configuration. It operates on standard 380V, three-phase power and fits seamlessly on any factory floor, thanks to its compact, floor-mounted design and manageable 320 kg weight. The blue and silver finish helps it stand out as a modern addition to any grain processing facility.

FAQs of Destoner Machine:

Q: How does the Destoner Machine remove stones from grains?

A: The Destoner Machine uses a combination of an inclined sieve and a precisely adjusted air blower to separate heavier impurities like stones from grains. As grains pass over the vibrating sieve, stones move in one direction while clean grains are collected separately, ensuring efficient stone removal.Q: What types of grains can be cleaned using this machine?

A: This machine is suitable for processing various grains such as rice, wheat, pulses, and other cereals. Its configurable settings ensure optimal cleaning efficiency across different grain types.Q: When is using a Destoner Machine recommended in grain processing?

A: A Destoner Machine should be used early in the grain processing sequence, typically right after initial cleaning and before further milling or packaging. This ensures that any stones or dense contaminants are removed to prevent machinery damage and improve product quality.Q: Where is the ideal installation location for this machine?

A: The Destoner Machine is designed for floor-mounted installation in grain mills, warehouses, or processing units. Its compact rectangular form and robust construction allow it to be situated in high-throughput or industrial production environments.Q: What is the process flow for operating the Destoner Machine?

A: Grains are loaded into the vibratory feeding system, which moves them onto the inclined sieve. Manual adjustment of air flow ensures precise separation of stones from grains. Cleaned grains exit through the automatic outlet, while stones and heavy debris are discharged separately.Q: How is the machine maintained, and what benefits does it offer?

A: Regular maintenance is minimal due to the machines corrosion-resistant finish and energy-efficient design. Benefits include high cleaning efficiency (up to 99%), consistent performance, low noise output, and reduced energy consumption, making it highly cost-effective for grain processors.Q: What control and safety features are integrated into the machine?

A: The destoner features PLC control for automated operation, along with a robust construction in stainless and mild steel. Manual air flow adjustment enables operator control, while the automatic discharge system promotes safety and ease of use during extended operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DeStoner Category

Yanmark Destoner

Price 130000 INR / Piece

Minimum Order Quantity : 1 Piece

Raw Material : Rice

Automatic : Yes

Warranty : 1 Year

Vibro Destoner

Price Range 250000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Raw Material : Rice

Automatic : No

Warranty : 1 Year